About GF Vehicle Assemblers Ltd The First Modern Vehicle Assembly Plant in Tanzania

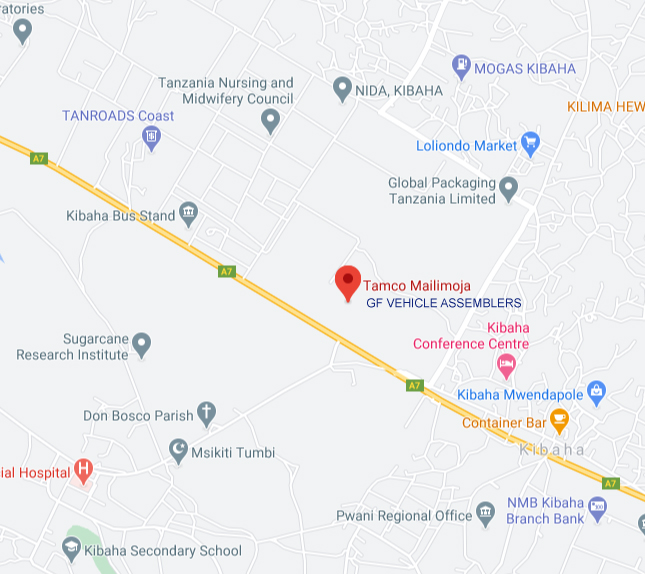

GF Vehicle Assemblers is the first modern age vehicle assembly plant located in Kibaha town, 35 kilometres West of Dar es Salaam, Tanzania.

The plant is designed to assemble various makes and models of light and heavy commercial trucks with a current capacity of 2500 units per annum.

Our Future Together

GF Assemblers has embarked on the journey to advance the motor vehicle sector in Tanzania. Our research and development team is geared towards finding mobility solutions that will be engineered and produced for Tanzanians, by Tanzanians at our manufacturing plant. A study of the Tanzanian market has given us a lot of insights, and we are considering various types of new products. Please stay tuned for more updates during the course of the exciting journey ahead, as we open a new chapter for the Tanzanian Vehicle Industry in Tanzania.

CORE VALUES - DIIRA

D-ependability

I-ntegrity

I-nnovation

R-eliability

A-ccountability

GUIDING PRINCIPLES

Quality We will produce outstanding products and deliver unsurpassed service that deliver premium value to our customers. Quality will be the first agenda in all meetings.

Keep it simple Simplicity eliminates bureaucracy. We will ensure that our processes and procedures are geared towards creating a productive and conducive working environment.

Work as a team We will promote the value of teamwork in everything we do while enhancing individual creativity.

Constant improvement Opportunities for improvement exist in all aspects of our work. We will foster a culture of continuous improvement and incremental change from the shop floor to top management.

Exceed customer expectations Our customers, both internal and external, are assured of excellence in delivery of products and services.

GF Assemblers is creating jobs in Tanzania. With a workforce of 100+ employees, we endeavour to train and upskill the workforce to deliver desired results and promote personal growth.

Since 2020, GFA offered systematic trainings that will enhance competencies of each level. GFA trainings have enhanced the job competency of employees by providing courses specialized for each job such as product quality, OEM/ Partner quality, Health & Safety etc. A special lecture for welded structures and other courses were provided to managers, engineers, and 100+ employees to complete GFA Training in 2020.

The production process is made up of three sections; assembly, body shop and paintshop that are fully equipped to handle semi and complete knocked down operations.

To enhance skills, team members undergo a variety of training programs on customer specific assembly processes, best manufacturing practices, quality assurance and safety.

The company has a dedicated quality team comprising quality inspectors and vehicle build process auditors. The team identifies critical check points and creates checklists thus assurance that the build is as per set standards.

Some of the equipment used in daily operations include:

• Torque calibrator

• Brake Tester and weighbridge

• Wheel alignment machine

• Water tester

Our supply chain department forms the backbone of the entire operations at GFA. It is here where all vehicle kits and parts are received, check against quality standards and stored to ensure that packing integrity is maintained.

The supply chain team also ensures that production lines are loaded as per demand and gives timely feedback to the manufacturer on the condition of kits together with improvements to the kits packaging and handling process.

ADDRESS

Plot 673 | TAMCO Industrial Park,

Kibaha, Tanzania

P.0.BOX 22692 Dar es Salaam.

CALL US NOW

+255 677 119 911FOLLOW US